Little Known Questions About Mfg.s

Wiki Article

The 3-Minute Rule for Manufacturing

Table of ContentsThe 4-Minute Rule for Hon Hai PrecisionFascination About Manufacturing IndustriesSee This Report on OemOem Can Be Fun For AnyoneExamine This Report about Hon Hai PrecisionIndicators on Lean Production You Should Know

The text on this page is an example from our complete White Paper 'Injection Moulding for Customers' - * Example message * - for complete guide click the download switch over! Introduction This guide is intended for individuals that are aiming to source plastic mouldings. It offers a much needed insight right into all that is entailed with developing plastic parts, from the mould device needed to the moulding procedure itself.If you intend to check out further, the guide covers sorts of mould tools, in addition to special finishing processes such as colours & plating. Words that are underlined can be located in the glossary in the appendix ... Component I: Moulding: The Essentials The Advantages of Shot Moulding Plastic injection moulding is an extremely accurate process that offers numerous advantages over other plastic handling approaches.

Precision is best for very elaborate components. You can hold this moulding in the hand of your hand and also it has managers, ribs, steel inserts, side cores and also openings, made with a gliding shut off function in the mould tool.

The Basic Principles Of Die Casting

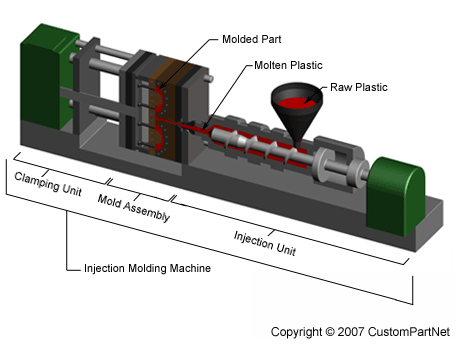

from product feed & melting; material shot; cooling time as well as ejection to the re-closing of the mould tool ready for the following cycle. Draft angles - The wall surfaces of a moulded part must be a little tapered in the direction in which the part is expelled from the mould device, to enable the part to be expelled quickly.

Ejector stroke - The pushing out of ejector pins to expel the moulded component from the mould device. Ejector stroke speed, length and timing requires to be very carefully controlled to avoid damages to the ejectors and mould device, yet at the exact same time make the moulding cycle as short as feasible.

Manufacturing Industries Fundamentals Explained

Ribs - When a plastic part has slim wall surfaces, ribs are included to the design to make the slim wall surfaces stronger Side cores - Side action which produces a function on a moulded component, at an opposing angle to the regular opening direction of the mould device. die casting. The side core requires to be able to retract as the plastic part can not be expelled or else.

Wall surfaces - The sides of a moulded part The message on this web page is an example from our complete White Paper 'Injection Moulding over here for Buyers'.

Shot moulding is extensively used for producing a range of components, from the tiniest parts to whole body panels of vehicles. Injection moulding makes use of a special-purpose maker that has three parts: the injection unit, the mould as well as the clamp.

The 4-Minute Rule for Additive Manufacturing

, with the quantity utilized of the previous being substantially higher.: 13 Thermoplastics are common due to qualities that make them very suitable for shot moulding, such as convenience of recycling, adaptability for a wide selection of applications,: 89 and also ability to soften and also stream on home heating.In multiple dental caries moulds, each tooth cavity can be the same as well as create the very same components or can be unique and also develop multiple various geometries during a solitary cycle. Moulds are normally made from device steels, but stainless steels and also aluminium moulds appropriate for specific applications. Aluminium moulds are normally improper for high volume manufacturing or components with narrow dimensional tolerances, as they have substandard mechanical buildings and are more go right here prone to put on, damages, and also contortion during the injection and also securing cycles; nevertheless, aluminium moulds are economical in low-volume applications, as mould fabrication prices as well as time are significantly decreased.

When enough product has gathered, the material is forced at high stress and also rate right into the part forming tooth cavity. The specific quantity of shrinkage is a feature of the resin being used, and can be fairly predictable. To stop spikes in stress, the process generally uses a transfer setting representing a 9598% complete dental caries where the screw changes from a constant speed to a continuous stress control.

All About Manufacturing Industries

Once the screw gets to the transfer setting the packaging stress is used, which finishes mould filling as well as makes up for thermal shrinking, which is rather high for thermoplastics family member to several various other materials. The packing pressure is applied up until the gate (cavity entry) strengthens. Because of its small dimension, eviction is generally the initial area to strengthen via its whole thickness.: 16 Once eviction strengthens, no even more material can go into the cavity; appropriately, the screw reciprocates and also acquires material for the following cycle while the product within the mould cools down to ensure that it can be expelled and be dimensionally stable.Report this wiki page